Application and features of GIZIN's ATC Camboxes

Introduction:

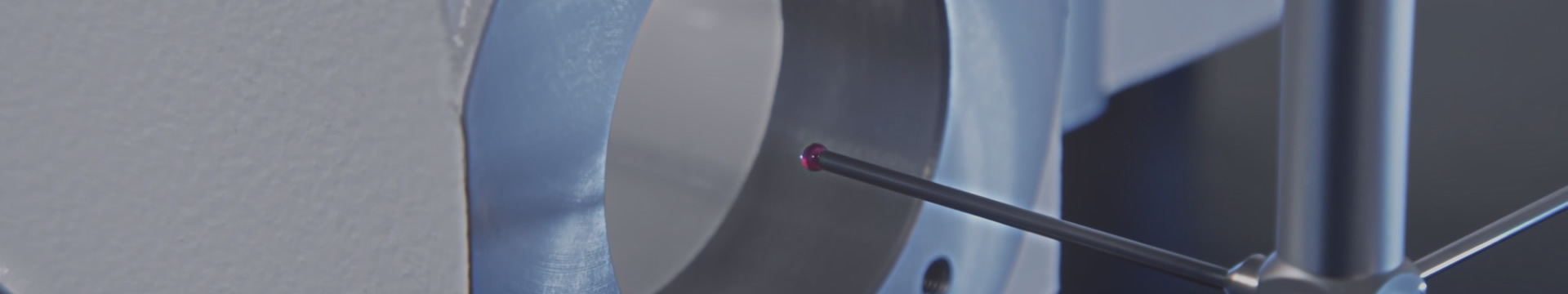

As a dedicated manufacturer of ATC camboxes, GIZIN is committed to providing high-quality solutions that enhance machining efficiency. Our ATC camboxes are designed to meet the demands of various industries, enabling seamless and automated tool changes. In this article, we highlight key industries that can benefit from our reliable and high-performance ATC camboxes.

Common Application of ATC Cambox

Automotive Manufacturing:

The automotive industry relies on efficient and precise machining processes. GIZIN's ATC camboxes are ideal for automotive manufacturers, facilitating rapid tool changes during the production of engine components, transmission parts, and chassis components. By minimizing downtime and ensuring accurate tool positioning, our camboxes contribute to improved productivity and consistent quality in automotive manufacturing.

Aerospace and Aviation:

In the aerospace and aviation sectors, precision and reliability are paramount. GIZIN's ATC camboxes excel in machining critical components such as engine parts, landing gear, and structural elements. Our camboxes' robust design, precise tool positioning, and rapid tool change capability contribute to efficient production processes, meeting the stringent requirements of the aerospace industry.

Medical Device Manufacturing:

The medical device industry demands exceptional precision and cleanliness in machining operations. GIZIN's ATC camboxes provide the necessary reliability and accuracy for machining medical implants, surgical instruments, and other medical device components. With rapid and precise tool changes, our camboxes contribute to the production of intricate and high-quality medical devices.

Mold and Die Making:

The mold and die industry requires precision and efficiency to produce complex and detailed molds and dies. GIZIN's ATC camboxes offer the rigidity, accuracy, and rapid tool changes necessary for machining intricate mold and die components. By reducing setup times and maintaining precise tool positioning, our camboxes enhance the overall productivity and precision of mold and die making.

Electronics and Semiconductor Manufacturing:

The electronics and semiconductor industries demand high precision and fast production cycles. GIZIN's ATC camboxes enable efficient tool changes during the machining of circuit boards, semiconductor components, and electronic devices. With our camboxes, manufacturers can achieve accurate tool positioning, contributing to improved production efficiency and product quality.

Energy and Power Generation:

In the energy and power generation sectors, GIZIN's ATC camboxes play a crucial role in machining components for turbines, generators, and power transmission equipment. The rapid tool change capability and precise tool positioning provided by our camboxes enhance the efficiency and accuracy of machining operations, ensuring reliable power generation.

Features of GIZIN ATC Cambox

The Fastest Tool Changer:

GIZIN's ATC camboxes are engineered to deliver industry-leading tool change speeds, minimizing downtime and maximizing production efficiency. Our advanced mechanisms and meticulous engineering guarantee swift and seamless tool changes, empowering businesses to achieve optimal machining performance.

Longest Product Life Cycle:

At GIZIN, we prioritize durability and reliability. Our ATC camboxes undergo rigorous testing and are constructed with high-quality materials, ensuring an extended product life cycle. By choosing GIZIN's ATC camboxes, you can trust in their longevity and consistent functionality, maximizing your investment.

Lightweight Products:

Recognizing the significance of reducing weight in machining operations, GIZIN designs ATC camboxes with lightweight materials without compromising strength and durability. This enables improved machine dynamics and reduced stress on machine spindles, enhancing overall performance and precision.

Modular Design for Customization:

GIZIN's ATC camboxes feature a modular design, allowing for flexible customization tailored to your specific requirements. With a wide variety of sizes, tool capacities, and configurations available, you can create a bespoke solution that perfectly aligns with your machining needs. Our modular approach ensures adaptability, versatility, and optimal integration into your existing setup.

Customized Products:

At GIZIN, we understand that each customer has unique machining demands. That's why we offer fully customized ATC camboxes, precisely engineered to your specifications. Our team of experienced engineers and technicians collaborates closely with you to comprehend your specific requirements, resulting in tailor-made ATC camboxes that optimize your machining processes. With our customization options, you can achieve unparalleled efficiency and productivity.

Conclusion:

GIZIN stands as your premier choice for advanced ATC camboxes, offering a comprehensive range of products with unparalleled features. Our commitment to speed, longevity, lightweight design, modularity, and customization ensures that you can select the perfect ATC cambox for your precise machining needs. With our cutting-edge technologies, meticulous craftsmanship, and customer-centric approach, GIZIN is your trusted partner in elevating your machining capabilities. Contact us today to explore our complete lineup of ATC camboxes and experience the pinnacle of precision and performance for your machining operations.