How Double Column VMCs and ATC Camboxes Power the Railway, Mining, and Heavy Industry Sectors

Introduction

In industries where strength, scale, and stability are non-negotiable—such as railway infrastructure, mining equipment manufacturing, and heavy industrial machinery—CNC machining solutions must be engineered to handle oversized, heavy-duty components with exceptional precision and reliability. Double Column Vertical Machining Centers (VMCs) have become essential tools in these sectors thanks to their large working envelopes, high rigidity, and structural stability. But to fully unlock their productivity potential, they must be paired with efficient, reliable Automatic Tool Changer (ATC) systems—and this is where our GIZIN ATC Cambox comes in.

________________________________________

Why Double Column VMCs Matter in Heavy Industries

Double column VMCs offer the structural strength and cutting capacity required to machine extra-large parts used in industries like:

- • Railway: bogie frames, couplers, brake components, and track sections

- • Mining: crusher housings, excavator arms, drilling platforms

- • Heavy Equipment: gearboxes, engine blocks, structural frames, and mold bases

These machines feature fixed double-column architecture that ensures minimal deflection even under heavy loads, making them ideal for roughing, semi-finishing, and finishing of high-mass parts.

However, such large-scale workpieces often require multi-tool operations, where the efficiency of tool change becomes just as critical as the machine’s rigidity and cutting power.

________________________________________

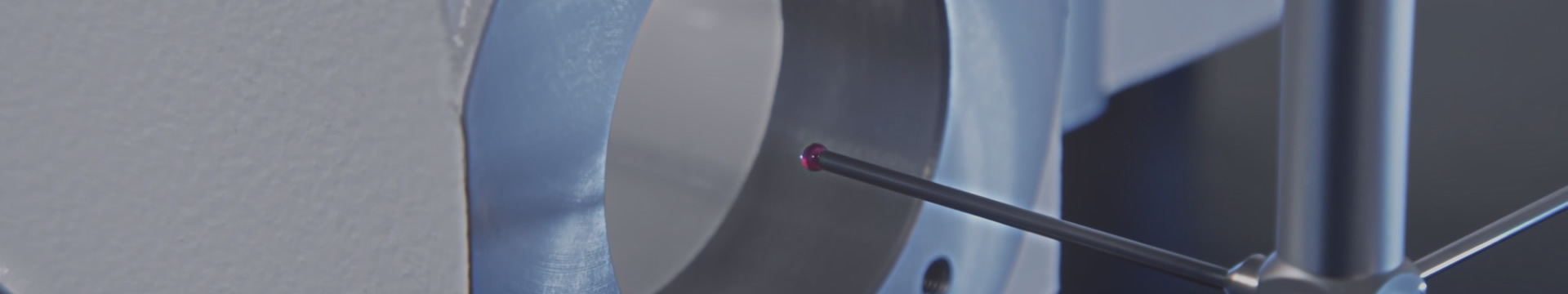

The Role of the ATC Cambox in Large-Part Machining

In the machining of large, complex parts, tool changes are frequent—and each one represents a potential point of failure if not executed with precision and stability. Our GIZIN ATC Cambox is specifically designed to support these demanding environments. It ensures:

- • Smooth and reliable tool changes, even under the stress of large cutter sizes and extended tool holders

- • Self-locking pin mechanisms that prevent tool drop during extraction or misalignment under load

- • Low-impact operation that reduces mechanical shock on the spindle and preserves machining accuracy

- • Minimal downtime, with efficient motion profiles that complement high-output production environments

For double column VMCs used in rail, mining, and heavy industry applications, the GIZIN ATC Cambox becomes an indispensable element—guaranteeing safe, repeatable, and rapid tool changes regardless of part size or cutting conditions.

________________________________________

Applications in the Field

Railway Sector

- • Components Machined: train undercarriages, brake beams, suspension mounts

- • Why it Matters: These parts are large, high-strength, and safety-critical. GIZIN’s ATC Cambox helps maintain precision across long production runs, ensuring tight tolerances even after hundreds of tool changes.

Mining Equipment

- • Components Machined: drilling supports, pump housings, rotary crushers

- • Why it Matters: Parts require large-diameter cutting tools and deep-pocket milling. The Cambox provides smooth tool transitions to avoid stress on the machine’s structural frame and spindle bearings.

Heavy Industry & Machinery

- • Components Machined: large die sets, press plates, steel mill parts

- • Why it Matters: Frequent tool changes between roughing and finishing passes are common. The ATC Cambox reduces idle time and ensures tooling is locked and aligned, even with heavier cutters.

________________________________________

Why Choose GIZIN's ATC Cambox for Double Column VMCs?

GIZIN's ATC Cambox is not a generic add-on—it’s an advanced, purpose-built system developed to meet the challenges of heavy-duty and large-format CNC machining. Here's why it stands out:

- ✅ Self-locking mechanism prevents tool drop during automatic changes

- ✅ Reduced spindle impact, protecting high-value spindles from shock damage

- ✅ Compatible with vertical and horizontal cam-type systems, including legacy machine retrofits

- ✅ Quiet, efficient, and reliable operation, even under prolonged use

- ✅ Field-proven in demanding applications across railway, energy, mold making, and mining

Whether you're building next-generation locomotives or massive excavators, your double column VMC deserves a tool-changing system that won't hold back its potential.

________________________________________

Conclusion

In railway, mining, and heavy industrial manufacturing, precision is vital—but so is endurance. Double column VMCs bring the structural capacity to machine massive components, but only when paired with a dependable ATC system like GIZIN’s Cambox can they truly reach peak efficiency.

From reducing downtime and tool wear to protecting your machine investment, the ATC Cambox is the quiet force behind smart automation in large-part machining.

Interested in upgrading or integrating a high-performance ATC Cambox into your VMC?

Contact GIZIN today—our team is ready to help you power up your machining capabilities for the world's toughest industries.