How GIZIN's ATC Camboxes Revolutionize CNC Operations for Manufacturers

Introduction

In the ever-evolving landscape of manufacturing, the quest for efficiency, precision, and flexibility remains paramount. GIZIN, a leading manufacturer of ATC (Automatic Tool Change) Camboxes, stands at the forefront of this innovation, providing solutions that significantly enhance the capabilities of CNC (Computer Numerical Control) machinery. Our ATC Camboxes are designed to meet the demands of manufacturers looking to elevate their production processes to new heights of automation and productivity.

GIZIN's ATC Camboxes: A Game-Changer for CNC Operations

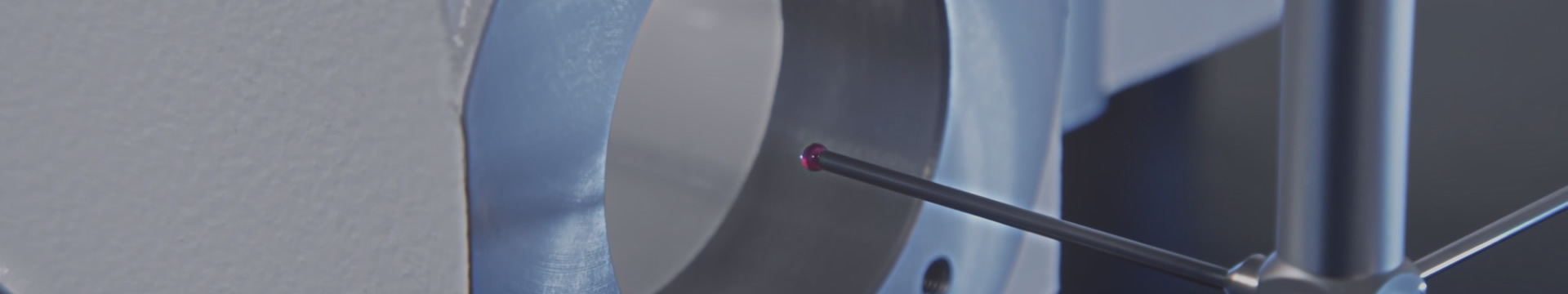

ATC Camboxes, engineered by GIZIN, automate the tool change process in CNC machines, a critical advancement for manufacturers aiming to optimize their operations. These systems are the heartbeat of modern CNC machinery, enabling rapid and precise tool changes that minimize downtime and maximize output. For manufacturers, this means an unparalleled improvement in efficiency and a competitive edge in the market.

Driving Efficiency Across Manufacturing Floors

GIZIN's ATC Camboxes are pivotal in transforming the manufacturing landscape. By automating tool changes, we help manufacturers slash cycle times and enhance machine utilization. This efficiency boost not only accelerates production rates but also supports the creation of more intricate designs within tighter timeframes. The result? An impressive uptick in productivity, with significant reductions in labor costs and operational downtime.

Precision and Consistency: The Hallmarks of Quality

In the realm of CNC machining, precision is not just a goal—it's a necessity. GIZIN's ATC Camboxes deliver unparalleled precision and consistency in tool changes, ensuring that every operation is executed with flawless accuracy. This meticulous precision fosters enhanced product quality, minimizing waste and rework. The consistency provided by our ATC systems is a cornerstone for manufacturers aiming to uphold the highest standards of quality.

Vertical ATC Camboxes V.S. Horizontal ATC Camboxes

Vertical ATC Camboxes are designed with a vertical orientation, making them particularly suitable for operations where space efficiency and precision are paramount. This design allows for a smaller footprint on the manufacturing floor, an essential factor for facilities with limited space. The vertical arrangement facilitates gravity-assisted tool changes, enhancing the precision and reliability of the tool change process. This setup is ideal for operations requiring high levels of accuracy and for manufacturers looking to optimize their workspace utilization.

On the other hand, Horizontal ATC Camboxes feature a horizontal orientation, offering advantages in terms of speed and flexibility. This design is particularly well-suited for high-volume production environments where rapid tool changes are critical to meeting production targets. The horizontal configuration allows for quicker access and faster tool changes, minimizing downtime and maximizing throughput. Additionally, horizontal ATC Camboxes can accommodate a wider range of tool sizes and types, providing greater flexibility in machining capabilities.

Flexibility for Tomorrow's Manufacturing Challenges

The manufacturing sector is characterized by its dynamic nature, with demands and designs constantly evolving. GIZIN's ATC Camboxes offer unmatched flexibility, allowing for the seamless integration of a wide array of tools. This versatility enables manufacturers to easily adapt to new designs and custom orders, ensuring a swift response to market changes without sacrificing operational efficiency or product quality.

The Future Is Automated with GIZIN

As we look towards the future, the role of automation in manufacturing becomes increasingly critical. GIZIN is at the cutting edge of this revolution, with our ATC Camboxes exemplifying how advanced technologies can redefine manufacturing processes. For manufacturers, partnering with GIZIN means not just keeping pace with industry advancements but setting new benchmarks for efficiency, quality, and innovation.

Conclusion

GIZIN's ATC Camboxes are more than just a component; they are a transformative force in CNC operations, driving efficiency, precision, and flexibility across manufacturing floors. For manufacturers seeking to leverage the benefits of automation, GIZIN offers not just products but solutions—solutions that promise a future where production limitations are a thing of the past. Embrace the heart of automation with GIZIN, and join us in shaping the future of manufacturing, where every challenge is met with an innovative solution.