The Distinct Advantages of Vertical vs. Horizontal ATC Camboxes

In the competitive landscape of CNC machining, manufacturers continuously seek innovative solutions to enhance efficiency, precision, and flexibility in their operations. A key component in achieving these goals is the Automatic Tool Change (ATC) Cambox, which plays a critical role in automating tool changes, thus significantly reducing downtime and improving productivity. GIZIN, as a leading innovator in this field, offers two distinct types of ATC Camboxes: Vertical and Horizontal. Understanding the differences between these two configurations is essential for manufacturers to make informed decisions that best suit their specific production needs.

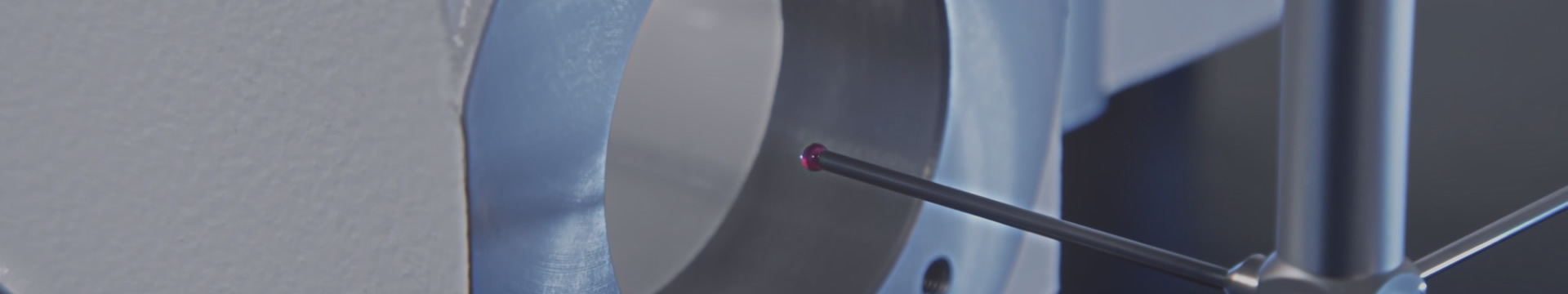

Vertical ATC Camboxes: Precision and Space Efficiency

Vertical ATC Camboxes are designed with a vertical orientation, making them particularly suitable for operations where space efficiency and precision are paramount. This design allows for a smaller footprint on the manufacturing floor, an essential factor for facilities with limited space. The vertical arrangement facilitates gravity-assisted tool changes, enhancing the precision and reliability of the tool change process. This setup is ideal for operations requiring high levels of accuracy and for manufacturers looking to optimize their workspace utilization.

Advantages of Vertical ATC Camboxes:

- Space-Saving Design: Their compact footprint allows for more efficient use of manufacturing floor space.

- Enhanced Precision: Gravity aids in the tool change process, providing additional stability and accuracy.

- Optimal for Complex Operations: Especially beneficial for intricate machining tasks that require high levels of precision.

Horizontal ATC Camboxes: Speed and Flexibility

On the other hand, Horizontal ATC Camboxes feature a horizontal orientation, offering advantages in terms of speed and flexibility. This design is particularly well-suited for high-volume production environments where rapid tool changes are critical to meeting production targets. The horizontal configuration allows for quicker access and faster tool changes, minimizing downtime and maximizing throughput. Additionally, horizontal ATC Camboxes can accommodate a wider range of tool sizes and types, providing greater flexibility in machining capabilities.

Advantages of Horizontal ATC Camboxes:

- Increased Speed: Facilitates faster tool changes, significantly reducing cycle times.

- Greater Flexibility: Accommodates a broader variety of tool sizes and types, allowing for versatile machining operations.

- High-Volume Production: Ideal for environments where production speed is a critical factor.

Choosing the Right ATC Cambox for Your Operations

When deciding between a vertical and a horizontal ATC Cambox, manufacturers must consider several factors, including:

1. The nature of their machining tasks,

2. Space constraints,

3. Production volume goals.

Vertical ATC Camboxes may be the preferred choice for operations where precision and space efficiency are top priorities, whereas horizontal ATC Camboxes could be better suited for high-volume production environments requiring speed and flexibility.

GIZIN's Commitment to Tailored Solutions

GIZIN understands that each manufacturer's needs are unique, and choosing the right ATC Cambox configuration is crucial to optimizing CNC operations. Our expertise in designing and manufacturing both vertical and horizontal ATC Camboxes ensures that we can provide tailored solutions that meet the specific demands of our clients. By partnering with GIZIN, manufacturers gain access to a wealth of knowledge and products that promise not just to meet but exceed their expectations for efficiency, precision, and flexibility in CNC machining.

In conclusion, whether your operations benefit more from the space efficiency and precision of a vertical ATC Cambox or the speed and flexibility of a horizontal ATC Cambox, GIZIN offers the cutting-edge solutions to propel your manufacturing processes into a future where excellence is the standard. Embrace the innovation with GIZIN, and let us help you make the choice that best fits your production needs, ensuring your place at the forefront of the manufacturing industry.