Automatic Tool Changers: Types, Working, Advantages, and Applications of ATC

Automation and robots have made life easier. With the advancement of technology, industries have started incorporating several automation tools to boost their production capacity. An automatic tool changer is also one of those automation tools that is widely used in the industry. A computerized numerical control, or CNC, machine tool can increase its productivity and tool carrying capacity by using an automatic tool changer, often known as an ATC.

Getting intrigued about knowing more about the automatic tool changers? We have got you covered. In this blog, we are going to discuss every aspect related to automatic tool changers so that you may better understand the types, working, advantages, and applications of using automatic tool changers.

Automatic Tool Changer

A CNC machine's ability to change tools fast without the assistance of a manual operator is improved by an automatic tool changer. By doing this, the ATC significantly lowers downtime on a particular project.

Automatic Tool Changers can also be used to replace worn-out or damaged tools. ATCs are typically utilized to increase a machine's ability to work with many tools at once. Automatic tool changers typically come in two styles: rotary-style and linear-style, and they differ in the number of tools they can hold.

Usually, an automatic tool changer includes:

1. Base

2. Gripper arm

3. Tool holder

4. Support arms

5. Tool Magazines(where the tool are stored)

Types of Automatic Tool Changers

You will observe that there are several types of Automatic Tool Changers. Technically, there are two distinct variations depending on the magazine's shape, i.e., Curved Travel and Straight Travel. Some of them are also designed as rotating holders. However, you can also purchase tool racks that are static and straight. The latter ones express a far better value despite being mechanically much easier. Additionally, the automatic tool changeover can be either horizontal or vertical, depending on how the magazine is positioned.

The Automatic Tool Changer, which is a necessary tool if you want the CNC machine to use multiple tools, can be quite helpful. Simply be sure you select the Automatic Tool Changer that best suits your requirements. When used properly, the ATC may offer amazing value and advantages, and the experience will undoubtedly sparkle. Just give it a shot, and you'll always reap more than wonderful rewards!

Working of An Automatic Tool Changer

The procedure for changing tools is the same, notwithstanding the many types of tool magazines. When the automatic tool changer gets the tool change signal, the spindle suddenly stops rotating and stops precisely at the tool change position, and the tool is discharged. The new tool then goes to the tool change position with the tool magazine and is cleared. The operation of changing tools is finished by clamping the spindle and moving it back to its initial processing position at the same time as the new and old tools are rotated on the spindle and the empty position of the tool magazine respectively.

Advantages of An Automatic Tool Changer

An automatic CNC tool changer offers several noteworthy advantages, such as:

1. The ability to switch between a variety of instruments without a human operator being needed

2. Higher precision

3. Improved effectiveness

4. Lower labor costs

5. Shortened total production time and interruptions

6. Increased capability for storing tools

7. More versatile machines

8. Improved equipment and staff safety

9. Being able to easily switch between larger and heavier tools

10. Increased edge polish as a result of better tooling selection for each procedure

Applications of an Automatic Tool Changer

Machines that remove material—such as mills, lathes, and CNC routers—are the primary beneficiaries of automatic tool changers (ATCs). Originally developed to reduce the need for manual tool swaps, ATCs have evolved into a core component of modern CNC automation. From basic 3-axis machines to advanced multi-axis systems, ATCs streamline operations by enabling quick and reliable tool changes without human intervention.

One area where ATCs are especially useful is in sheet metal and mold machining, where tool rearrangement is frequent and downtime is costly. Instead of manually halting operations to swap between end mills, drills, reamers, or engraving bits, the ATC—equipped with a reliable Cambox system—automatically manages the transition, improving throughput and operator efficiency.

Machine Types That Benefit from ATCs:

- • Vertical Machining Centers (VMCs): Often used for general-purpose part production, VMCs paired with ATCs enable rapid tool changes between roughing and finishing tools, significantly shortening cycle times.

- • Horizontal Machining Centers (HMCs): Known for their stability and chip evacuation, HMCs utilize ATCs to handle complex multi-face machining, supporting higher tool counts and longer unattended operation.

- • Double Column/Gantry Machines: Common in the machining of large components such as molds, dies, and structural parts, these machines rely on high-capacity ATC Cambox systems to manage diverse tooling needs across long machining cycles.

- • Mill-Turn and Turn-Mill Machines: In multitasking machines where turning and milling are combined, ATCs are essential for quick transitions between different types of tools, maintaining accuracy without stopping the spindle.

- • 5-Axis Machining Centers: These machines perform multi-surface machining in a single setup. ATCs with precision Camboxes support high-speed, multi-angle tool swaps, ensuring optimal tool access and consistent quality.

Industry Applications:

- • Aerospace: High-precision, lightweight components such as turbine blades and structural ribs require multi-tool strategies. ATC Cambox systems enable seamless transitions between finishing and roughing tools while maintaining extreme accuracy.

- • Automotive: Engine blocks, gear housings, and suspension parts are produced in high volumes. ATCs contribute to non-stop production by minimizing idle time between tool changes.

- • Energy Sector (Wind, Oil & Gas): The machining of large castings and complex profiles—such as turbine housings or valve bodies—benefits from heavy-duty ATC systems capable of handling long, large-diameter tools with stability.

- • Mold & Die Making: Tool changes are frequent and critical in mold machining due to the need for surface quality and geometry transitions. A reliable ATC Cambox enables smooth, vibration-free tool swaps and improves tool life.

- • Medical Equipment: Surgical implants and custom instruments demand extreme precision and repeatability. ATCs ensure exact tool positioning and reduce human error in sensitive operations.

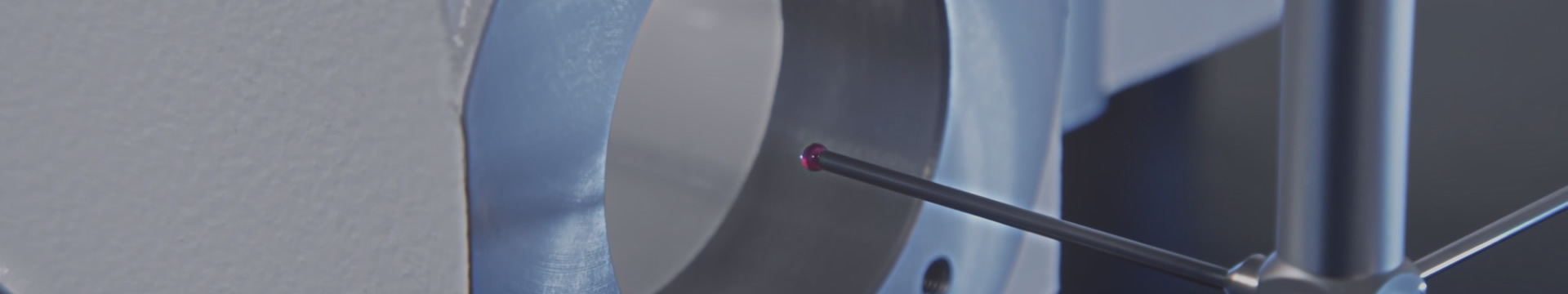

An automatic tool changer typically includes a base, gripper-equipped arms, a tool holder, support arm, and tool magazines. For maximum reliability, these systems must be well synchronized with the CNC's motion and toolpath strategy. At GIZIN, our ATC Cambox is engineered to meet these demands with high-speed performance, self-locking safety mechanisms, and compatibility across vertical, horizontal, and gantry machine platforms.

By integrating ATCs—especially high-performance Cambox solutions—manufacturers can reduce cycle time, eliminate manual errors, and unlock the full potential of modern CNC machines across multiple industries and machine types.

Final Thoughts

Automatic Tool Changers, or ATC, is the lifeline of the production industry. These tools have entirely automated the tool-changing procedures and have boosted production. With a comprehensive line of goods for all varieties of CNC machining centers and CNC lathes, Gizin specializes in computer numerically controlled (CNC) machine tools and automatic tool changers (ATC).

If you are looking for an automatic tool changer supplier to automate your tool change process and boost your production capabilities, then look no further and contact Gizin now.